iNFRASTRUCTURE projects

Behind every beautiful building Sterling erects lies a complex labyrinth of electrical, mechanical and engineering ingenuity simplified to synchronize and make things happen. While architected and produced behind the scenes post-interior build, Sterling Construction are experts at planning, designing and building critical, advanced infrastructure projects that match the quality and expertise of the company’s public facing work. Please take a few moments to experience some of our completed Infrastructure projects below.

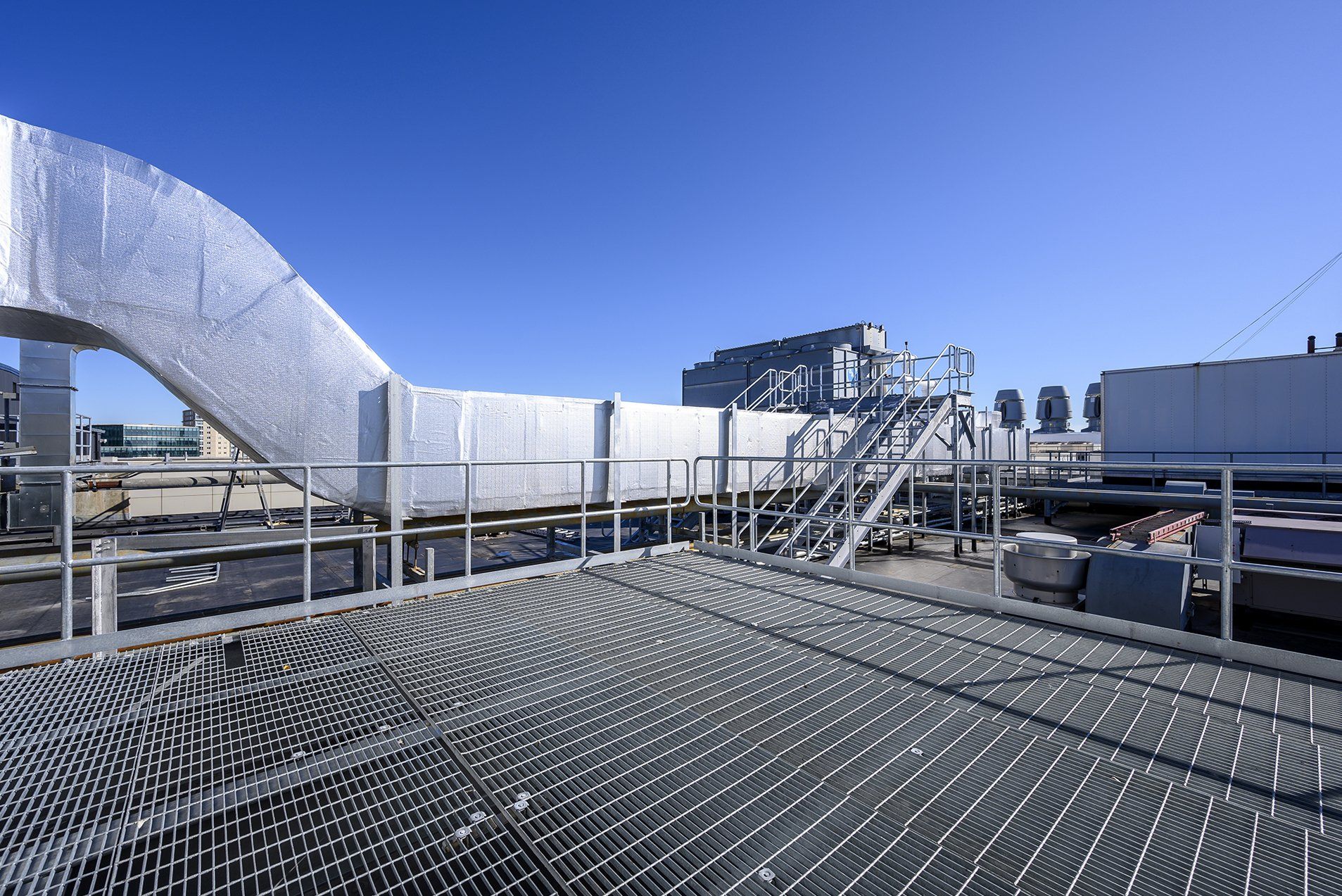

RELATED BEAL | 451D STREET, SOUTH BOSTON, MA

The Related Beal project included the design-assist and construction of infrastructure improvements to an existing a 9-story, 451,000 sq. ft. building to covert an occupied office building to house multiple future lab tenants. The project required precision communication, coordination and logistics between all parties during the complex 4-month pre-construction and 6-month construction phases. Comprised of; new MUA’s and EAHU systems, energy recover systems, ductwork distribution, 4000 amp distributed electrical service, standby emergency power systems, structural improvements, gas risers, PH systems, HHW plant and risers and a chemical storage unit, the extensive project was a challenging multi-team effort achieved within an occupied environment. Sterling coordinated multiple phases and shutdowns to ensure occupied operations where not negatively impacted.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

ARDENT MILLS | AYER, MA

The Ardent Mills project included the development of an advanced wheat heater / steam system on the top of an 8-story mill building to optimize the complex process of converting wheat to flour. Owned by Cargill Corporation, the project required the installation of rooftop, redundant boiler systems to boil and pre-heat wheat shells to enable easier removal as part of their 24 / 7 operation. Due to strict zoning and hazardous locations requirements, and coupled with a dangerous low flash point for heating wheat, Sterling Construction adhered to extreme safety precautions to minimize risk during and after construction. As testament to producing exemplary work, Sterling was awarded a 2nd project to develop and construct two 50,000 CFM MUA’s with separate exhaust systems with large structural reinforcements as well as new ductwork and exhaust systems throughout the entire 8-story building.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

27 DRYDOCK INFRASTRUCTURE | BOSTON, MA

The 27 Drydock Infrastructure project included the conversion of a partial office building into additional, fully modernized laboratory space in the Seaport District in Boston, MA. The Sterling team installed new standby power and main electrical systems to enable seamless business operations for multiple tenants on 9 floors within this 270,000 sq. ft. building.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton